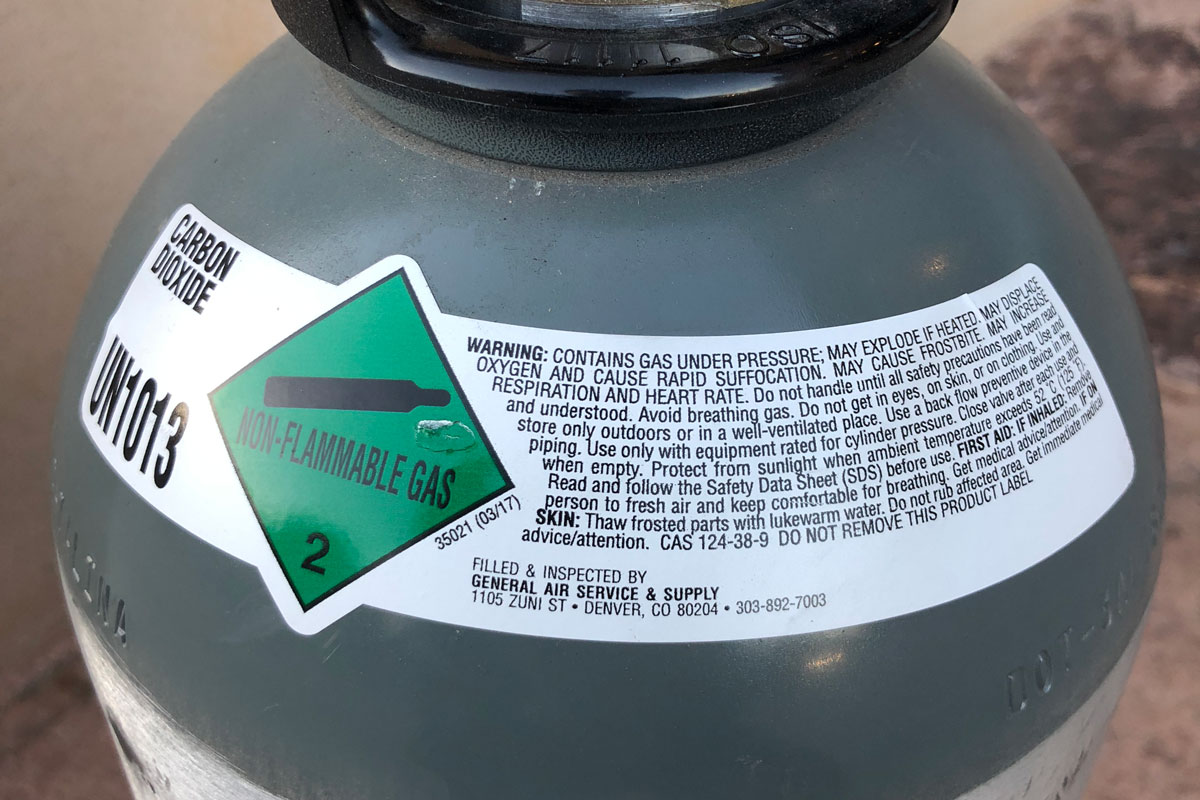

On April 7th the Brewers Association, along with the Beer Institute, and several other industry groups, including the Compressed Gas Association, signed a letter to Vice President Mike Pence expressing “strong concern that the current coronavirus (COVID-19) pandemic creates a significant risk of a shortage in carbon dioxide (CO2).” The letter further noted that “A…

Category: Suppliers

La Red Cervecera Perú (Lima)

During my last week in Lima, at the beginning of August, I took myself to Barranco to get acquainted with the Red Cervecera Perú. Red Cervecera is arguably one of Peru’s premiere homebrew supply retailers. Located in a remodeled old early-Republican house on Avenida Francisco Bolognesi, the Red Cervecera combines a homebrewing supply retail shop,…

Admiral Maltings’ “Open Malthouse Day”

On February 10th, I attended Admiral Malting‘s “Open Malthouse Day”, hosted by Admiral’s founders, Ron Silberstein (of ThirstyBear Brewing) and Dave McLean (of Magnolia Brewing), as part of San Francisco Beer Week. Guests were taken on thirty- to forty-minute behind-the-scenes of the malthouse, where we were able to learn about and observe the full production…