Sadly, I have another brewery closure to announce. This time it is that of Buck Wild Brewing, an award-winning gluten-free brewery in Oakland’s Jack London Square District. Buck Wild was 100% gluten-free, from the brews to the bites, and one of the few places around where celiacs and gluten-sensitive folk could confidently order from the…

Author: juan

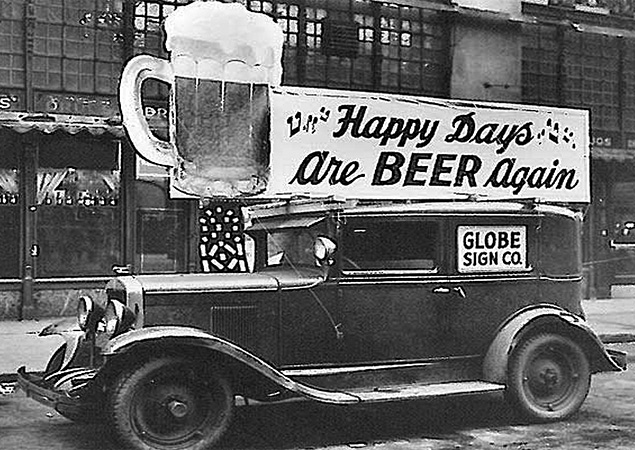

April 7th: National Beer Day

Why is April 7th “National Beer Day”? Well, it’s because it was on that date in 1933 that the production and distribution of beer became once again legal in the United States. On March 14, 1933, Representative Thomas H. Cullen introduced House Resolution 3341, which would amend parts of the Volstead Act, which was the…

We Say Goodbye to Barranco Beer Co.

Early this morning, Lima’s Barranco Beer Company abruptly announced via its Instagram account that it will be closing its doors after this weekend. No explanation was given. After ten years in business, having survived the pandemic shut-down, Barranco Beer looked to be a steady feature of the Lima, and Peruvian, craft beer scene. Barranco Beer…

Tres Diablos, by Danville Brewing Co.

If you’re in the area, you should drop in at Danville Brewing Co. and get a pour or two of Tres Diablos. Tres Diablos is DBC’s excellent SF Beer Week triple IPA release. It clocks in at 10% abv and 130 IBU, and is hopped with Nelson and Mosaic. It is pleasantly bitter, with fruity…